In today’s competitive market, businesses need efficient solutions to package products neatly and professionally. Messy or improperly packed items can harm brand perception and reduce customer satisfaction. This is where shrink wrap machines play a crucial role, transforming disorganized products into uniform, visually appealing packages. By automating the wrapping process, these machines ensure consistency, reduce waste, and protect items from damage during transportation. Companies across industries are leveraging wrap machines to streamline operations, enhance product presentation, and maintain hygiene standards. Understanding how these machines work can help businesses maximize efficiency and maintain high-quality packaging standards.

The Basics of Shrink Wrap Machines

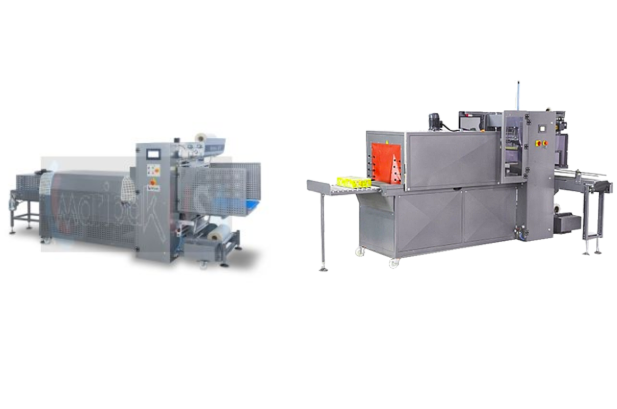

These are designed to enclose products in a protective plastic film that shrinks tightly when heat is applied. This method is widely used across industries, from food and beverage to electronics and retail. The primary advantage of using shrink wrap machines is their ability to create uniform packaging that looks professional and secure. They can handle items of varying shapes and sizes, ensuring that each product receives a snug fit. Additionally, shrink wrap minimizes exposure to dust, moisture, and contaminants, particularly for sensitive products such as electronics or perishable goods.

How Shrink Wrap Machines Improve Product Appearance

A major benefit of shrink wrap machines is the enhancement of product appearance. Messy or irregularly shaped items can be difficult to display effectively on shelves or during shipping. Shrink wrap ensures a smooth, clean finish, making products more visually appealing to consumers. This uniformity not only enhances aesthetics but also strengthens the product’s perceived value. Retailers and manufacturers often notice increased sales when products are presented neatly, as customers are more likely to trust and choose items that appear professional and well-packaged.

Efficiency and Time-Saving Benefits

Another key advantage of them is operational efficiency. Manual packaging can be time-consuming and inconsistent, particularly for businesses handling large volumes of products. Automated shrink wrap systems accelerate the packaging process, allowing workers to focus on other critical tasks. The consistent application of shrink film reduces errors, rework, and material wastage. By streamlining these processes, companies can reduce labor costs and improve overall productivity. Efficient packaging also means faster shipment times, which is crucial for meeting customer expectations in fast-paced industries.

Protection and Durability

Shrink wrap provides more than just aesthetic benefits; it also protects products during transport and storage. Using shrink wrap machines, businesses can safeguard items from scratches, dust, and moisture, ensuring they reach customers in perfect condition. This is particularly valuable for fragile or high-value products, where damage could lead to costly returns and dissatisfied clients. The tight seal created by shrink wrap also helps prevent tampering, adding an extra layer of security.

Customization and Versatility

Modern machines offer high flexibility, allowing businesses to customize packaging to their needs. Machines can handle various film types, thicknesses, and print options, enabling branding, logos, or promotional messaging to be applied directly to the packaging. This versatility is especially beneficial for businesses aiming to enhance brand recognition while maintaining consistent product presentation. From bundling multiple items together to creating individual retail-ready packages, shrink wrap machines provide a solution for diverse packaging challenges.

Conclusion

Using shrink wrap technology transforms messy, irregular products into neat, professional, and market-ready packages. By improving appearance, efficiency, protection, and customization, shrink wrap machines are an essential tool for businesses across industries. They not only streamline operations but also enhance customer perception and product value. For companies looking to further optimize their packaging process, investing in industrial packaging machines can complement shrink wrap systems, offering scalable solutions that improve productivity, reduce waste, and ensure consistent quality across all products.